Not every day is the same in drainage!

Sometimes very exciting things can happen and DALROD Bath & Swindon know this all too well. The team recently had a day of spectacular firsts which started out ordinarily enough when we went to help a customer with their drainage pipes.

The commercial property had experienced some recent flooding and required some urgent repairs. Upon investigation it was discovered that the issue was caused by a 4-inch cast iron pipe underneath the shop which had sprung a leak. The predictable April showers and heavy rainfall had quickly brought the problem to the surface.

Finding a suitable solution…

From the customers perspective the very last option would be to dig up his shop floor, putting his business out of action. So, a range of alternative choices were assessed. Restricted access into the pipe meant that neither no dig patch lining nor a complete liner would be suitable without extensive challenges. However, this is where having a close supplier relationship can prove extremely beneficial. We reached out to our supplier CJ Kelly International for advice, and it became obvious this job was a perfect fit for a new product on the market.

Martyn Kelly commented on the situation “we have worked closely with James from DALROD for a couple of years now and when this came up it was something really great to get our teeth into together. Using advancing technology within the field of drainage is something we promote quite strongly and this is why we enjoy the relationship we have with the Relining Group. You cannot beat the excitement that comes with a new product and the chance to use it practically within the field!”

New opportunities for innovative technology.

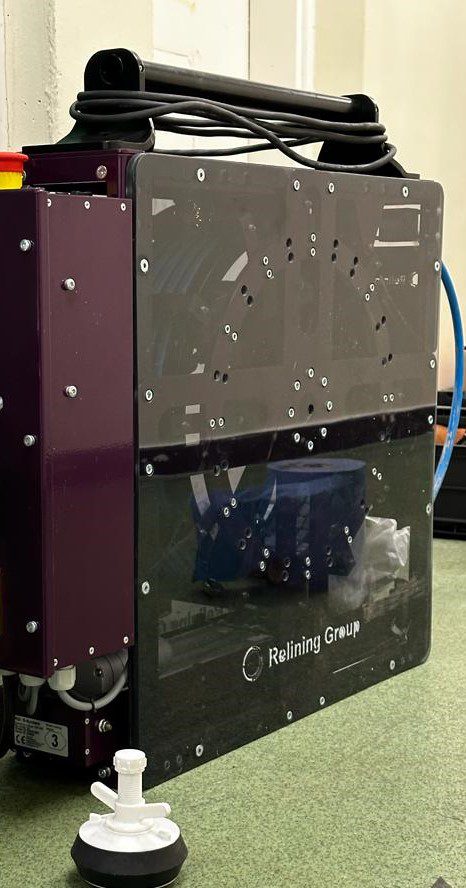

Excitement gathered as we realised we were going to be the first to use the brand new S System for brush coating from the Relining Group in the UK in the field.

James Kelly from DALROD Bath & Swindon said “we felt privileged to be given the opportunity to use this technology for the first time. Having products come to the market that make our lives as engineers easier and cause less disruption to the customer are always going to be winners!”

“It was a pleasure to go through the training together with James who is a such a professional and who has a long experience from the industry. As well as getting the positive feedback and “approval” of our system. We are very pleased to work together with Martyn and John from J C Kelly Int. Ltd. because we know they can provide a technical support for the contractors in the UK. As always it´s very important to choose the right partners when implementing a new market as well as a new product,” said Kaarlo Bergdahl Sales Manager from Relining Group Int. Oy”

How does it work?

This impressive system works by brushing the inside of the pipe with layers of resin, allowing the operator to gradually build up layers inside the pipe. The resin application seals the pipe and provides a smooth finish and with an average curing time of only five short minutes between coats, this system allows multiple applications in a short space of time.

After a thorough clean of the pipes using both chains and high pressure water jets, the pipe can then be carefully dried using a hot air blower to remove any remaining moisture. The result means that by using the S System technology the pipe can be coated, finished and put back into use very quickly.

The restricted access points still proved challenging, but the small pipes delivering the resin to the brushes were ideal for delivering a new sealed pipe coating for the customer. Even better, he was able to keep his floor!

Great reviews!

The product was so successful that we are already looking ahead to the next project for the S System. Challenging access is once again the key driver, plus short sections of pipe requiring coating to seal them off from holes in the pipework make this the natural choice.

If you would like to know more about the technology involved, or would like to discuss any drainage requirements with us, then please contact our team at DALROD on 01225 984195.